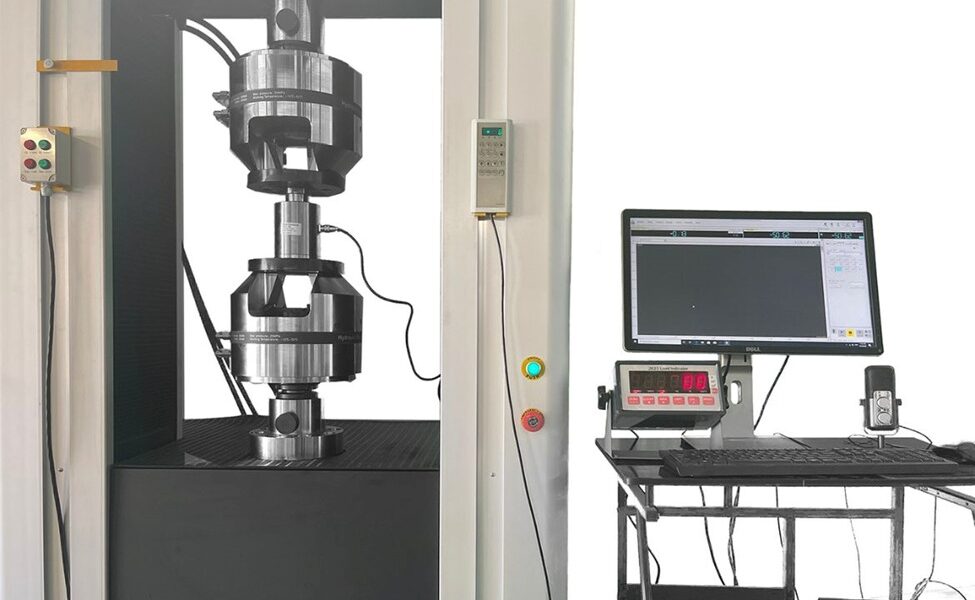

Top 5 Industries Rely on Universal Testing Machines for Quality Control

Universal Testing Machines (UTMs) work behind the scenes, making sure that products we use daily are safe, reliable, and up to standard. By subjecting materials to rigorous tests—stretching, compressing, bending—UTMs reveal their true capabilities and limitations. From the cars we drive to the buildings we inhabit, UTMs play an important role in maintaining quality in many sectors. In this article, we will discuss 5 industries where UTMs are fundamental to quality control.

Top 5 Industries Rely on UTMs

While UTMs play a fundamental role in numerous industries, there are 5 industries that rely on them for stringent quality control. Taking a closer look at these industries and understanding how UTMs are used in their daily operations, let’s explore them further.

- Automotive Industry

In the automotive sector, UTMs are a crucial tool for assessing materials and components’ strength and durability. Manufacturers use these machines to test metals, plastics, and composites that constitute vehicle parts. For instance, tensile tests determine materials’ ability to withstand pulling forces, which is crucial for components like seat belts and suspension systems. Compression tests evaluate how materials respond to pressing forces, vital for assessing structural elements such as the chassis and body panels. By conducting these tests, manufacturers can verify that each component meets safety standards and performs reliably under different conditions.

Moreover, UTMs facilitate the development of innovative materials aimed at optimizing vehicle performance and safety. By providing precise data on material behavior under different stresses, these machines enable engineers to design lightweight and robust components, contributing to fuel efficiency and occupant protection. The automotive industry’s dedication to quality control is illustrated by its reliance on UTMs to verify that all materials and parts comply with regulatory requirements and can endure real-world use.

- Aerospace Industry

The aerospace industry demands materials that can withstand extreme conditions, including high stress, temperature fluctuations, and pressure variations. UTMs are used to test the tensile and compressive strength of aircraft and spacecraft materials, such as aluminum alloys and composite materials. These tests confirm that components like wings, fuselage sections, and landing gears meet stringent safety and performance standards. By taking advantage of UTMs, aerospace engineers can verify that materials will perform reliably under flight conditions.

Additionally, UTMs assist in the development of new materials and technologies within the aerospace sector. By understanding how materials behave under varying stresses, engineers can innovate and improve designs, leading to more efficient and safer aircraft. The critical nature of aerospace applications makes UTMs indispensable in assuring that every component can withstand operation at high altitudes and speeds.

- Construction and Infrastructure

In construction, guaranteeing materials’ structural integrity is a key priority. UTMs are used to test building materials like concrete, steel, and timber for their load-bearing capacities and resistance to forces such as tension and compression. For example, tensile tests on steel reinforcement bars confirm their ability to handle stretching forces without breaking. These tests are necessary for constructing safe and durable buildings, bridges, and other infrastructure projects.

- Medical Device Manufacturing

The medical device industry relies on UTMs to make sure that products like implants, surgical instruments, and prosthetics meet strict safety and performance criteria. Materials used in medical devices must be biocompatible and capable of withstanding mechanical stresses during use. UTMs test these materials for tensile strength, flexibility, and fatigue resistance to make sure that they perform reliably in the human body. For instance, testing the tensile strength of sutures provides assurance that they won’t break during surgery, while fatigue testing of joint implants determines whether they can withstand repeated movements over time.

By conducting these tests, manufacturers can identify potential weaknesses in materials or designs, leading to safer and more effective medical devices. UTMs in this industry are crucial for maintaining patient safety and assuring that healthcare products perform as intended under diverse physiological conditions. UTMs help meet regulatory standards and gain approval from health authorities, which is a necessity for bringing medical devices to market.

- Manufacturing and Consumer Goods

Manufacturers of consumer goods, ranging from electronics to household appliances, use UTMs to test their products’ durability and performance. For example, in the electronics industry, UTMs assess the strength of connectors and circuit boards’ flexibility to verify that they can withstand everyday use. In the packaging industry, UTMs test the strength of materials like plastics and cardboard to make certain they protect products during shipping and handling. By conducting these tests, manufacturers can improve product quality, reduce failure risk, and increase customer satisfaction.

UTMs used in this sector are diverse, covering a broad spectrum of products and materials. By making sure that consumer goods meet quality standards, manufacturers can build trust with customers and reduce product recalls or failures. UTM testing data informs design improvements and material selection, leading to more reliable and durable products on the market.

Reliable UTMs for Quality Control in Industry

A Universal Testing Machine is indispensable in a variety of industries, providing assurance of the quality and safety of materials and products. From the automotive and aerospace industries to construction, medical device manufacturing, and consumer goods production, UTMs provide critical data on material properties that guide design and manufacturing decisions. There is a need for these machines to be highly reliable; dependable UTMs provide accurate and consistent results, helping industries to maintain compliance, improve product performance, and maintain consumer trust. Investment in robust and precise UTMs remains a cornerstone of effective quality control strategies as technology advances.

Top 5 Industries Rely on Universal Testing Machines for Quality Control

Universal Testing Machines (UTMs) work behind the scenes, making sure that products we use daily are safe, reliable, and up to standard. By subjecting materials to rigorous tests—stretching, compressing, bending—UTMs reveal their true capabilities and limitations. From the cars we drive to the buildings we inhabit, UTMs play an important role in maintaining quality in many sectors. In this article, we will discuss 5 industries where UTMs are fundamental to quality control.

Top 5 Industries Rely on UTMs

While UTMs play a fundamental role in numerous industries, there are 5 industries that rely on them for stringent quality control. Taking a closer look at these industries and understanding how UTMs are used in their daily operations, let’s explore them further.

- Automotive Industry

In the automotive sector, UTMs are a crucial tool for assessing materials and components’ strength and durability. Manufacturers use these machines to test metals, plastics, and composites that constitute vehicle parts. For instance, tensile tests determine materials’ ability to withstand pulling forces, which is crucial for components like seat belts and suspension systems. Compression tests evaluate how materials respond to pressing forces, vital for assessing structural elements such as the chassis and body panels. By conducting these tests, manufacturers can verify that each component meets safety standards and performs reliably under different conditions.

Moreover, UTMs facilitate the development of innovative materials aimed at optimizing vehicle performance and safety. By providing precise data on material behavior under different stresses, these machines enable engineers to design lightweight and robust components, contributing to fuel efficiency and occupant protection. The automotive industry’s dedication to quality control is illustrated by its reliance on UTMs to verify that all materials and parts comply with regulatory requirements and can endure real-world use.

- Aerospace Industry

The aerospace industry demands materials that can withstand extreme conditions, including high stress, temperature fluctuations, and pressure variations. UTMs are used to test the tensile and compressive strength of aircraft and spacecraft materials, such as aluminum alloys and composite materials. These tests confirm that components like wings, fuselage sections, and landing gears meet stringent safety and performance standards. By taking advantage of UTMs, aerospace engineers can verify that materials will perform reliably under flight conditions.

Additionally, UTMs assist in the development of new materials and technologies within the aerospace sector. By understanding how materials behave under varying stresses, engineers can innovate and improve designs, leading to more efficient and safer aircraft. The critical nature of aerospace applications makes UTMs indispensable in assuring that every component can withstand operation at high altitudes and speeds.

- Construction and Infrastructure

In construction, guaranteeing materials’ structural integrity is a key priority. UTMs are used to test building materials like concrete, steel, and timber for their load-bearing capacities and resistance to forces such as tension and compression. For example, tensile tests on steel reinforcement bars confirm their ability to handle stretching forces without breaking. These tests are necessary for constructing safe and durable buildings, bridges, and other infrastructure projects.

- Medical Device Manufacturing

The medical device industry relies on UTMs to make sure that products like implants, surgical instruments, and prosthetics meet strict safety and performance criteria. Materials used in medical devices must be biocompatible and capable of withstanding mechanical stresses during use. UTMs test these materials for tensile strength, flexibility, and fatigue resistance to make sure that they perform reliably in the human body. For instance, testing the tensile strength of sutures provides assurance that they won’t break during surgery, while fatigue testing of joint implants determines whether they can withstand repeated movements over time.

By conducting these tests, manufacturers can identify potential weaknesses in materials or designs, leading to safer and more effective medical devices. UTMs in this industry are crucial for maintaining patient safety and assuring that healthcare products perform as intended under diverse physiological conditions. UTMs help meet regulatory standards and gain approval from health authorities, which is a necessity for bringing medical devices to market.

- Manufacturing and Consumer Goods

Manufacturers of consumer goods, ranging from electronics to household appliances, use UTMs to test their products’ durability and performance. For example, in the electronics industry, UTMs assess the strength of connectors and circuit boards’ flexibility to verify that they can withstand everyday use. In the packaging industry, UTMs test the strength of materials like plastics and cardboard to make certain they protect products during shipping and handling. By conducting these tests, manufacturers can improve product quality, reduce failure risk, and increase customer satisfaction.

UTMs used in this sector are diverse, covering a broad spectrum of products and materials. By making sure that consumer goods meet quality standards, manufacturers can build trust with customers and reduce product recalls or failures. UTM testing data informs design improvements and material selection, leading to more reliable and durable products on the market.

Reliable UTMs for Quality Control in Industry

A Universal Testing Machine is indispensable in a variety of industries, providing assurance of the quality and safety of materials and products. From the automotive and aerospace industries to construction, medical device manufacturing, and consumer goods production, UTMs provide critical data on material properties that guide design and manufacturing decisions. There is a need for these machines to be highly reliable; dependable UTMs provide accurate and consistent results, helping industries to maintain compliance, improve product performance, and maintain consumer trust. Investment in robust and precise UTMs remains a cornerstone of effective quality control strategies as technology advances.